Energy waste rarely announces itself with a flashing red light.

Most of the time, it slips out quietly—through a failing roof membrane, leaky windows, uninsulated walls, or aging mechanical systems. By the time a problem becomes visible inside the building, you’ve often already paid for it several times over in wasted energy, moisture damage, and emergency repairs.

Drone-based thermal inspections change that equation. They give you a fast, safe, and visual way to see exactly where your building is losing heat—across an entire facility or campus—without scaffolding, lifts, or guesswork.

For facility managers, building owners, and the marketing and communications teams who support them, this kind of visual data isn’t only a maintenance tool. It’s also powerful storytelling and documentation: proof of due diligence, sustainability efforts, and capital improvement ROI.

Let’s break down how drone inspections help you “fix” building heat loss—practically, safely, and in a way that can be clearly communicated to stakeholders.

What “Building Heat Loss” Really Looks Like in the Real World

Heat loss isn’t a single problem; it’s a cluster of related issues that show up in different ways:

- Roofing failures

- Wet or saturated insulation under a membrane

- Seams and penetrations where warm air escapes

- Ponding water that leads to long-term moisture and structural issues

- Wall and façade problems

- Thermal bridging at structural elements

- Missing or compromised insulation in panels or cavities

- Failing joints around expansion gaps and cladding

- Windows, doors, and openings

- Leaky curtain walls and storefront systems

- Gaps around overhead doors in loading docks and warehouses

- Aging weatherstripping that no longer seals

- Mechanical and utility losses

- Steam line leaks

- Inefficient rooftop units (RTUs) running hot

- Poorly insulated piping and ductwork

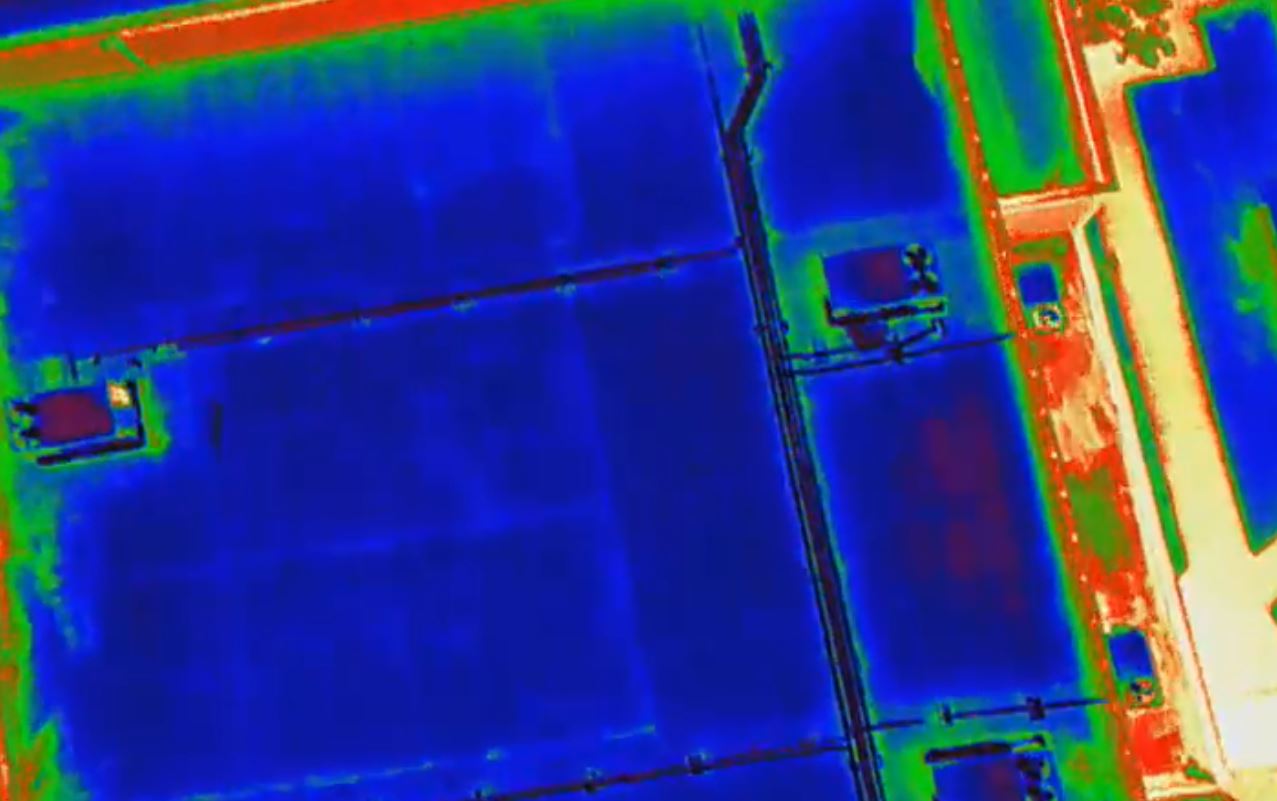

All of these issues show up as temperature anomalies—areas that are warmer or colder than they should be relative to surrounding surfaces. Thermal cameras mounted on drones capture this delta and translate it into clear, actionable visuals.

Why Traditional Inspections Miss So Much

Conventional building envelope inspections rely heavily on:

- Walking the roof with a handheld thermal camera

- Lift-based checks of façades

- Visual inspections from the ground

- Trial-and-error destructive testing

Those methods can work—but they’re:

- Slow and labor-heavy

- Limited in coverage (you see only what you can safely reach)

- Dependent on the inspector’s vantage point and experience

- Potentially disruptive to building operations

In large facilities—corporate campuses, industrial plants, logistics hubs, healthcare complexes—it’s easy for problem areas to stay hidden for years simply because no one can see them safely, quickly, and comprehensively.

Drone inspections step over those limitations.

How Drone-Based Thermal Inspections Work

A modern building heat-loss drone survey typically includes two data layers:

- Thermal (infrared) imagery – to show temperature anomalies

- High-resolution visual imagery – to document physical conditions

Here’s what the process looks like when it’s done professionally:

1. Pre-Planning

- Review site constraints (airspace, nearby airports, local restrictions)

- Map building footprints, roof levels, obstructions, and critical areas

- Coordinate with building management for access, timing, and safety

2. Optimal Timing and Conditions

Thermal inspections depend on contrasts. The best results typically come when:

- There’s a clear difference between indoor and outdoor temperatures

- The building has gone through a heating or cooling cycle

- Direct sunlight and reflective surfaces are managed to avoid false positives

An experienced drone crew plans flight schedules to maximize this contrast and minimize noise in the data.

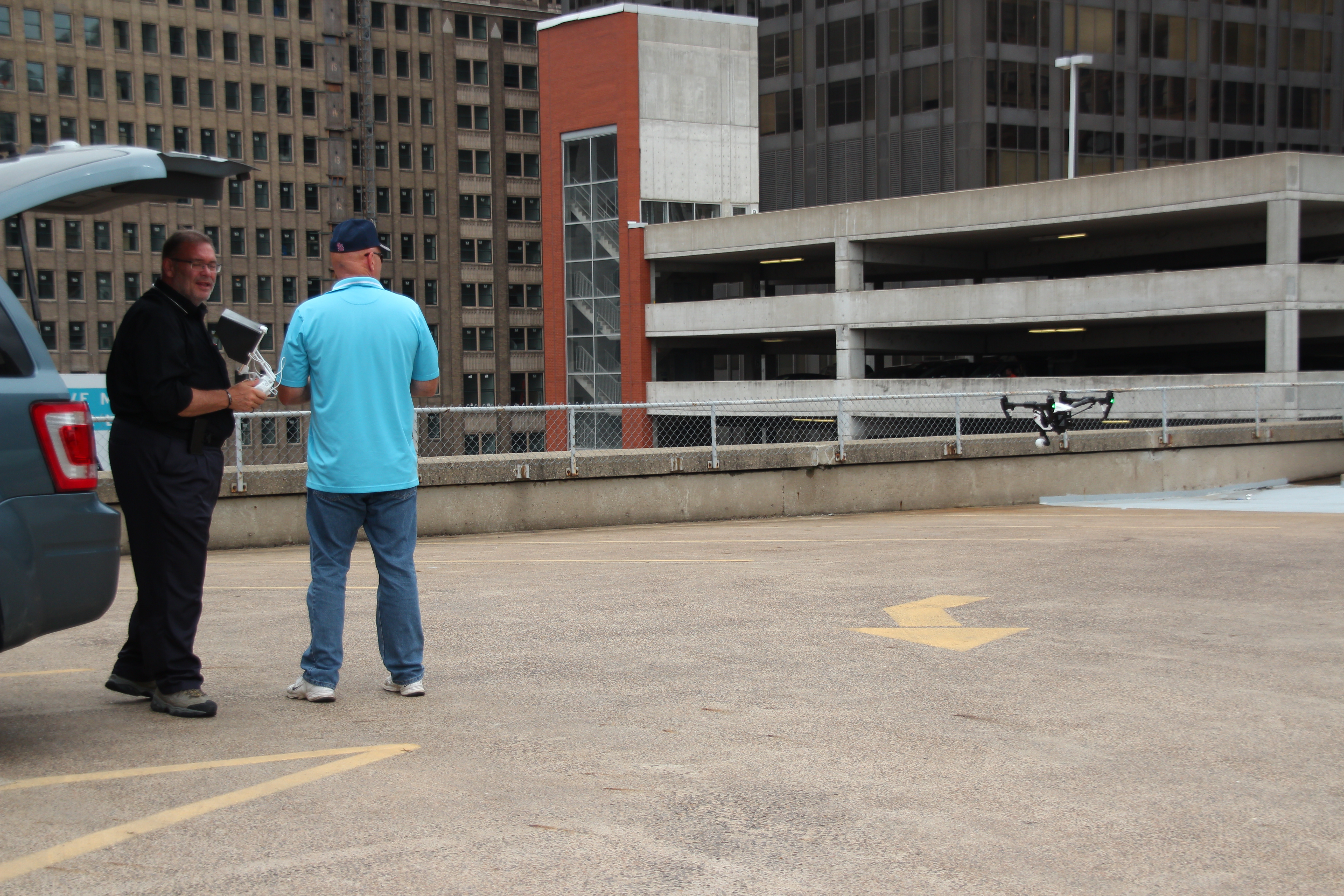

3. Flight and Data Capture

Using specialized drones equipped with radiometric thermal sensors, the crew:

- Flies precise grid patterns over roofs and façades

- Captures overlapping thermal stills and/or video

- Collects matching high-res visual imagery for context

With the right gear and pilots, an inspection that would take days on lifts can often be captured in a fraction of the time—with no one leaving the ground.

4. Analysis and Interpretation

Raw thermal data is only half the job. The real value comes from:

- Comparing thermal images with visual imagery to understand what’s happening at each anomaly (e.g., seam failure, wet insulation, missing insulation, mechanical issue)

- Creating maps and reports that align anomalies with real-world locations and roof or building drawings

- Flagging priority areas by severity, risk, and likely cause

This is where pairing commercial drone pilots with a seasoned imaging and post-production team pays off. You’re not just getting “cool pictures”—you’re getting usable intelligence.

Where Drone Thermal Inspections Deliver the Biggest Wins

1. Commercial Roofs

Flat and low-slope roofs are a perfect fit for drone thermography. Aerial thermal imagery can reveal:

- Wet or saturated insulation

- Failing seams, flashings, and penetrations

- Heat loss around HVAC curbs, vents, and skylights

Instead of guessing where to core sample or cut, you target the exact spots that show anomalies—reducing destructive testing and focusing repair budgets where they matter.

2. Building Envelopes and Façades

From high-rise office towers to big-box retail, drones can scan façades quickly and safely to detect:

- Missing or poorly installed insulation

- Thermal bridging at structural elements and anchors

- Air leakage around windows, doors, and façade transitions

For owners, this is invaluable evidence when evaluating contractor work, planning façade upgrades, or developing long-term capital budgets.

3. Industrial and Utility Infrastructure

Drone-based thermal imaging is also effective for:

- Steam tunnels and pipe runs

- Heat exchangers and process equipment

- Mechanical rooms and rooftop units (when accessible to line-of-sight)

Being able to capture both thermal and visual data from elevated angles gives maintenance teams an immediate short list of what to address first.

Turning Technical Data into Clear Visual Communication

You’re not just fixing heat loss; you’re also justifying budgets, demonstrating ESG progress, and communicating risk and ROI to non-technical audiences.

That’s where expert video and photography production comes in. Thoughtful post-production can transform your drone capture into:

- Executive-ready presentations

- Before/after visuals of problem areas and completed repairs

- Simple overlays that show thermal anomalies alongside the visible image

- Callouts and annotations explaining what each hotspot means

- Board and investor updates

- Short, narrated explainer videos that walk through issues, solutions, and projected savings

- Visual documentation of capital improvements tied to sustainability and resilience goals

- Marketing and ESG storytelling

- Branded micro-videos and stills demonstrating your commitment to energy efficiency

- Visual proof that your organization is proactive about infrastructure health, not reactive

When drone and thermal inspections are paired with a professional studio and post-production team, you’re not just checking boxes—you’re creating a visual asset library that supports operations, compliance, and brand.

Planning a Drone Inspection Program That Actually Pays Off

To get maximum value from building heat-loss inspections, treat them as a structured program, not a one-off event.

Consider:

- Baseline Survey

- Capture current conditions across roofs, façades, and key mechanical areas

- Identify and rank anomalies by risk and cost impact

- Targeted Repairs and Upgrades

- Use the visuals to guide contractors directly to problem zones

- Prioritize “quick win” fixes with strong ROI

- Follow-Up and Verification Flights

- Confirm completed repairs actually resolved the thermal issues

- Build a “before and after” visual record for internal and external stakeholders

- Ongoing Monitoring

- Schedule periodic inspections (annually or after major weather events)

- Track trends over time to anticipate failures before they become critical

When your inspection assets are captured and processed by an experienced imaging partner, each year’s data layers cleanly onto the last. Over time, you build a visual history of the building’s performance that’s hard to dispute—and incredibly valuable.

Why Professional Production Quality Matters

Anyone can buy a drone and a thermal camera. Very few can:

- Fly safely and legally in complex environments

- Capture usable, consistent images and video that align with inspection goals

- Color-grade, annotate, and edit that footage into a coherent story for decision makers

- Deliver footage and stills in formats that your engineers, contractors, marketing team, and executives can all use without frustration

That’s the gap a dedicated video studio fills—translating raw technical capture into polished, clear, and versatile visual assets.

Partner with St. Louis Video Studio for Drone Heat-Loss Inspections

St. Louis Video Studio is an experienced, full-service professional commercial photography and video production company with the right equipment and creative crew experience for successful image acquisition—on the ground and in the air.

We offer full-service studio and location video and photography, as well as editing, post-production and licensed drone pilots. St. Louis Video Studio can customize your productions for a wide range of media requirements, from technical inspection documentation to executive briefings and marketing campaigns.

Repurposing your photography and video branding to gain more traction is another specialty. We are well-versed in all file types, styles of media and accompanying software, and we use the latest in Artificial Intelligence for all our media services—from smart noise reduction and image enhancement to AI-assisted editing and content versioning.

Our private studio lighting and visual setup is perfect for small productions and interview scenes, and our studio is large enough to incorporate props to round out your set. We support every aspect of your production—from setting up a private, custom interview studio to supplying professional sound and camera operators, as well as providing the right equipment—ensuring your next video production is seamless and successful.

For inspections that demand unique perspectives, we can even fly our specialized drones indoors where appropriate and safe, capturing views that traditional methods simply cannot reach.

As a full-service video and photography production corporation since 1982, St. Louis Video Studio has worked with many businesses, marketing firms and creative agencies in the St. Louis area for their marketing photography and video. Whether you’re documenting building heat loss, showcasing repairs, or telling a broader story about your organization’s commitment to efficiency and sustainability, we’re ready to help you capture it—and communicate it—clearly.